Top selling products

-

Sale!

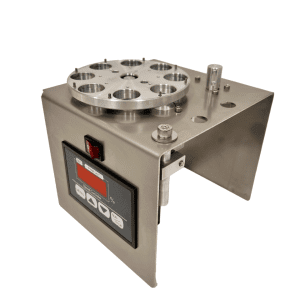

AGS Brass Annealer 3.2 – .416 Cheytac, .50BMG

US $ 330.00Original price was: US $ 330.00.US $ 297.00Current price is: US $ 297.00. Add to cart -

Sale!

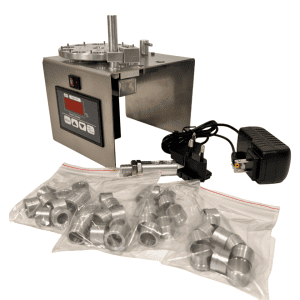

AGS Brass Annealer 3.1

US $ 299.00Original price was: US $ 299.00.US $ 269.10Current price is: US $ 269.10. Select options -

Sale!

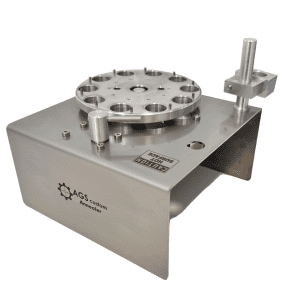

AGS Brass Annealer 3.0

Rated 5.00 out of 5US $ 290.00Original price was: US $ 290.00.US $ 261.00Current price is: US $ 261.00. Select options -

Sale!

AGS Brass Annealer 2.0

Rated 5.00 out of 5US $ 260.00Original price was: US $ 260.00.US $ 234.00Current price is: US $ 234.00. Select options -

Sale!

AGS Brass Annealer

Rated 4.98 out of 5US $ 210.00Original price was: US $ 210.00.US $ 189.00Current price is: US $ 189.00. Select options

What we do

AGS Custom parts and accessories - home of the AGS Brass annealer - affordable, simple and compact annealing machine. AGS annealer is made with shooters needs on our mind. From shooter for shooters.

Basic info

• Uniformity of case neck tension will allow you to seat your bullets with less run out

• It will give you more consistency in your reloads

• Depending on the model, AGS Annealer accepts calibers up to 50 BMG

• Adjusting between calibers under 60 seconds

• AGS Annealer has super small footprint, only 6x6"

In addition

• It will restore your case necks to ‘like new’ condition

• It will extend the life of your cartridge cases

• It will reduce your reloading cost and improve accuracy

Basic info

• Uniformity of case neck tension will allow you to seat your bullets with less run out

• It will give you more consistency in your reloads

• Depending on the model, AGS Annealer accepts calibers up to .50 BMG

• Adjusting between calibers under 60 seconds

• AGS Annealer has super small footprint, only 6x6"

In addition

• It will restore your case necks to ‘like new’ condition

• It will extend the life of your cartridge cases

• It will reduce your reloading cost and improve accuracy

“Product was ordered on Monday 10/4/21 arrived Friday 10/8/21. Visa processing was excellent. Product was excellent. Product runs as expected. Stephan is a honest man and makes an honest product. The world could use more men like him. Where others would rip you blind, he does business the way honest men do business. From Serbia to KY USA in 4 days in the middle of a Covid crisis. WOW! Stephan is one tight group shooter.”

Kevin

“Your annealer really has great reviews and the YouTube videos were of great help to me in deciding to buy your product and not someone else’s. I must commend you on its design and functionality, I look forward to using it.”

Simon

“I received the annealer today. Looks perfect and I performed just a simple function test. Works great. All is good and I’ll be letting my friends know about your annealer. Thank You!”

Bruce

“Wow! In France on Saturday and here on Monday. And it works, Thank for the great product.”

Patrick

“I just received my annealer yesterday all the way to Arizona and got a chance to use it last night. I am really impressed so far and it was very consistent once I got it setup. Thanks”

Chuck

“Good Morning Stefan: I thought I would let you know I got the machine all set up. I did raise the height of it about an inch because I was having trouble with the case dropping straight up and down even though I had the tray in place the way it was supposed to be. But after that I ran 200 in an hour and it runs GREAT!!!”

Steve

“I did my 1st load of cases and really pleased with the annealer. The nozzle on a UK gas gun is abt 15mm, but I have overcome this. All the Best”

Vince

“The annealer arrived today despite being in rural area.BUT, it’s here and in great shape and I’m looking forward to using it. Just have to find the right charger. What I’ve got is either not enough amps or too much. Thanks for being so helpful.”

Randy

“Overall – this is a very well built unit & works great: good job. Thks”

Ron

“The unit arrive today. This is the fastest shipment I have experienced, even faster than its power supply that I bought locally and haven’t arrived until now 🙂 Solid, very well made and compact. Can’t wait to try. Thanks for such a good service.”

Rob

Precision with AGS Annealer

- Affordable Precision Annealing

- Lightweight & Compact Design

- Easy-to-Use Maintenance-friendly Solution

2019 Best Quality

Awards Winner

The World's Most Powerful Industry

International Awards for Access

What we do for you!

Get best industrial services

for your business

95%

Providing quality

Numbers Speak

A Decade of Crafting Precision Annealing Machines

- Innovative Solutions

- Intuitive Operation

- Precision Reliability

- Cost Savings

- Conveniently compact

- Consistent Reloads

2754

47

10

3

Crafting Precision Solutions

Gear Up for Precision, Innovation, and Unmatched Excellence!

- Our Mission

- Our Vision

- Our History

At AGS Custom Parts, our mission is to empower shooters with cutting-edge solutions. We strive to deliver reliable and innovative products, ensuring precision and satisfaction in every shot.

- Innovative Solutions for Shooters

- Reliable Performance in Every Product

- Enhancing Precision Shooting Experiences

- Industry-Leading Quality Standards

- Global Community of Satisfied Shooters

- Confidence in Shooting Excellence

For two decades, AGS Custom Parts has been at the forefront of designing and producing top-notch shooting accessories. Our rich history is a testament to our commitment to quality, innovation, and customer satisfaction.

- Proven Track Record of 20 Years

- Continuous Innovation and Evolution

- Customer Satisfaction as Our Legacy

We're thriving and

building better products

Conatct us

Reach Out to AGS Custom

For inquiries, cooperation, or expert advice, feel free to reach out. We’re here to elevate your shooting experience with our reliable and innovative products. Contact us today and let’s embark on a journey towards precision.

Do you need any help?

Frequently asked questions

Annealing should be done every reload. This will eliminate the spring back, and give repeatable and smooth sizing.

The primary reason for annealing rifle brass is preventing case-necks from cracking and keeping them in the same hardness range. They will eventually split because firing and resizing cases “work hardens” brass, making the thin necks brittle. Most rifle cases will survive 4-5 firings, and some will last longer, depending on the brand and method of resizing.

Annealing is a process which helps to restore the ductility of the brass. That makes it easier to size and less likely to crack or split, so annealed brass cases can be used many more times before they are in need of replacing.

Yes you can, and we don’t want to do it, because it can lead to dangerous situations, since the brass can get too soft. Common method is to use a chemical indicator in the form of heat sensitive paint – Tempilaq seems to be the most common brand used.

Annealing cases more than once, as long as it’s not still hot on the second go, doesn’t do anything negative.

Its all down to prefference. Double burner setup will anneal your cases faster.

Our Latest News

What's going on in our blog?